The Master line motors stand out for the flexibility of their electrical and mechanical design, resulting in a high-performance product, complying with the international standards and aligned with the global trends.

Motorized brush lifting implies important advantages in the performance of the motor throughout the years:

These motors are recommended in cases in which the load has a high resistant torque or high inertia at starting. The external resistances are used only to start the motor providing high torque and strongly reducing the inrush current. The brushes are in contact with the collector rings only at starting which avoids unnecessary wearing of the brushes and collector rings during rated operation allowing a longer time of use of the set.

Examples

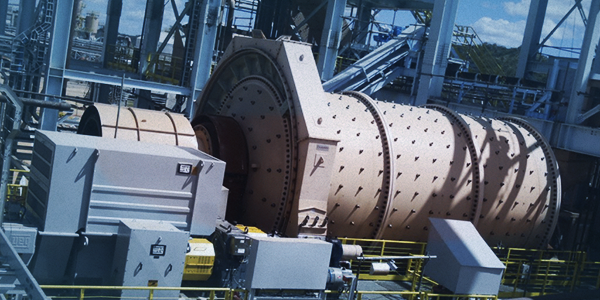

Ball mills, fans, exhaust fans, crushers, pumps in general and others.