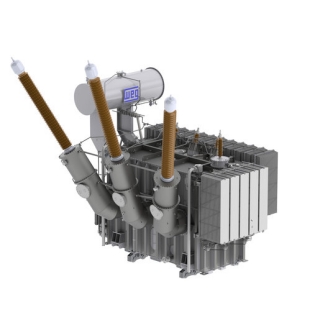

Large power transformers are designed to ensure high performance in a variety of applications and market segments, meeting the specific needs of power companies and of the industry in general.

The transformers with output above 50,000 kVA are responsible for adjusting the voltage among the different parts of the circuit in large power systems, enabling the power transmission in medium and long distances as economically as possible.

Their most common application is in power utility companies, where they interconnect the power generation and transmission systems with the local distribution systems; however, they can also be used in large industry substations.

WEG power transformers are designed to ensure high performance in a variety of applications and market segments, meeting the specific needs of the power companies and of the industrial segment in general.

The verticalization of the manufacturing processes (making the electrical insulating varnish, electric wires, tanks, insulating kits, coatings, etc.) is a remarkable characteristic and advantage of WEG, allowing broad quality control of the different production phases, as well as flexibility in lead times.

A wide network of accredit Technical Assistants is present all over Brazil, ensuring fast, local technical service and support to WEG's customers.

Applications