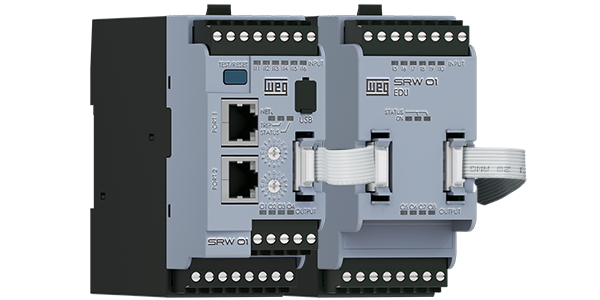

The smart relay SRW01 series is a low-voltage, electric motor management system with state-of-the-art technology and network communication capabilities. Its high reliability and precision make the SRW01 suitable for the toughest industrial applications.Additionally, its modular concept allows easy functionality expansionsit and wide application coverage. The main function of the SRW01 is to protect and control electric motors in their most diverse industrial applications. Due to its reduced size and modular design, the relay is frequently used when space for its assembly is a determining point, The on-line monitoring options, failure diagnosis and failure statistics allow preventive maintenance to be more effective, thus reducing the number of downtimes. It covers wide application for continuous process plants in the following market segments.

The relay offers pre-programmed operating modes that perform some types of standard starting and monitoring conditions. Its friendly parameterization mode allows users to program the relay according to their needs.

The SRW01 supports the following communication networks protocols: DeviceNet, Modbus-RTU, and Profibus-DP.

The communication modules can be easily exchanged due to its plug and play capabilities.

The SRW01 has a modular design, providing easy assembling and integration.

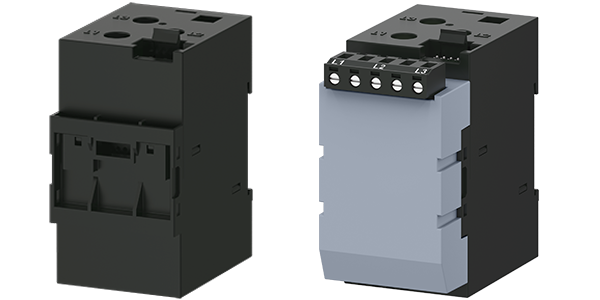

The Control Unit (UC) can be assembled with the Current Measuring Unit (UMC) or current and voltage measuring unit (SRW01-UMCT), forming a single unit, or separated (up to 2 meters).

The SRW01 has pre-programmed operation modes, which operates in several kinds of starting and monitoring modes. One of them is the transparent mode that can be programmed according to your needs, making the SRW01 fit to the most diverse applications.

The SRW01-UC Control Unit provides LED indicators for input and output activations, status, operation mode, power supply status, failure and alarm status.

The mounting of the Control Unit can be done either by 35 mm DIN rail or onto back panel mounting.

Communication protocols: DeviceNet, Modbus, and Profibus are defined using proper protocol installed in the communication drawer.

The Plug and Play concept automatically recognizes and configures the SRW01 for safe operation, avoiding manual error configuration.

The use of a Digital Expansion Unit (EDU) provides to the SRW01 smart relay the availability of 6 digital inputs and 4 digital outputs in addition to those already existing in the Control Unit (UC), which can be used for various purposes such as devices monitoring command, status or alarm signaling, among others.

The Current Measuring Unit (UMC) measures the current of the three motor phases.

Using a current and voltage measuring unit (UMCT), in addition to measuring the motor currents (as in the UMC), it is also possible to monitor voltages up to 690 V ac, phase sequence, power factor, all the motor powers and make management and electric power consumption (kW/h).

The values are digitally transmitted to the Control Unit (UC).

The WLP is the SRW01 configuration software for Windows environment with user friendly interface that enables system parametrization, programming, controlling and monitoring.

The WLP software enables the user to configure the relay, edit parameters and program in LADDER.

Through the WLP configuration assistants the user has a guided routine that enables relay configuration. When necessary, the relay can be programmed in LADDER using mathematical and control blocks.

Its high reliability and precision make the SRW01 suitable for the toughest industrial applications. The on-line monitoring options, failure diagnosis and failure statistics allow preventive maintenance to be more effective, thus reducing the number of downtimes. It offers wide application for continuous process plants in the following market segments: