The third generation of the MVW01 offers power arms with a new cooling system and an electric panel with a new thermal dissipation design that allows a greater range of power output when compared to the previous version.

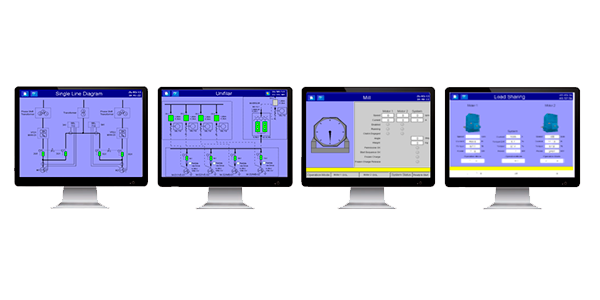

The MVW01 third generation also introduces the new 10” touchscreen HMI that provides the operator an easy interaction to program the drive, access and read the parameters, configure the exhibition mode (letters size, idioms, colors, etc.), create graphics and also, by means of pop-up windows, see text messages as alarms, trips, error log, help, etc.

Applied for a wide range of industrial applications that require variable speed control, such as compressors, pumps, fans, conveyor belts, mills, etc. or to start high power motors (synchronous or asynchronous).

The MVW01 third generation is an efficient and reliable solution that not only enables process speed control but also provides energy savings, high efficiency, reducing operation & maintenance costs as well as the total cost of ownership (TCO).

Main Reasons to Use the MVW01

10-inch touch screen HMI mounted on the MVW01 door offers great flexibility to the operator allowing easy access to user process data in real time. The intuitive operation makes the tasks of parameterizing the equipment, reading status and recording alarms / faults simpler.

It also supports multiple languages, various levels of protection against unauthorized access as well as graphing and plotting functions.

Assembly features

Software features

Optional features

Special Assembly Features

Special Software Functions