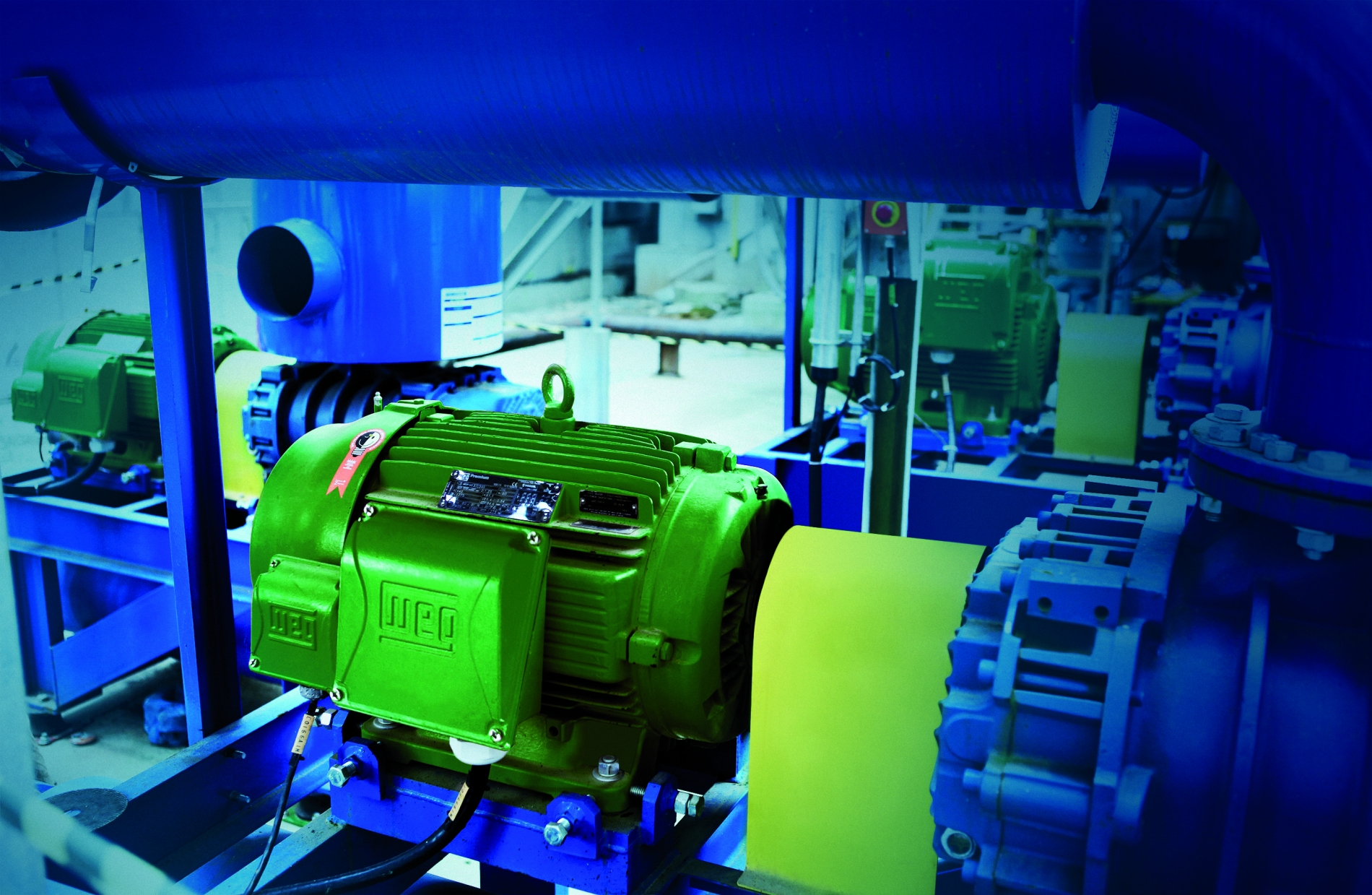

Electric motors are the heartbeat of modern industry, powering everything from conveyor systems in mining to packaging lines in food production. As energy costs rise and sustainability mandates tighten, choosing the right motor isn’t just a technical decision, it’s a strategic one. For Canadian industries looking to optimize performance, VJ Pamensky (WEG Canada) offers access to some of the most efficient and technologically advanced electric motors available today.

Motor efficiency has undergone a dramatic transformation over the past 30 years. While standard efficiency once sufficed, today's benchmarks are higher, especially with the adoption of NEMA Premium efficiency standards. These motors meet the current NRCAN federal regulations and NP motors like our W22 motors, engineered to deliver lower total cost of ownership through reduced energy consumption and maintenance.

But efficiency isn't just a number. It’s a measure of how well a motor converts electrical energy into mechanical power with minimal losses. As modern facilities demand more uptime and better energy control, the bar for what qualifies as "efficient" continues to rise.

Recent advancements in electric motor technology are enabling WEG to reach unprecedented levels of efficiency. Key innovations include:

These engineering improvements work together to deliver higher power density, quieter operation and longer service life, all essential for today’s demanding industrial environments.

NEMA Premium motors are designed with energy savings in mind. These motors often achieve 1–4% higher efficiency than standard models, which may seem small, but for continuous-run applications, it can mean thousands of dollars in annual energy savings.

More importantly, they contribute to carbon reduction goals. For companies in sectors like mining or oil & gas, where motors often operate 24/7, adopting NEMA Premium motors is a critical step toward meeting internal sustainability targets and government regulations.

Modern electric motors don’t operate in isolation. When integrated with variable frequency drives (VFDs) and smart motor control systems, they become part of a broader industrial automation ecosystem.

VFDs offer precise speed control and soft-start capabilities, which reduce mechanical stress and save energy. Smart systems can monitor temperature, vibration and load conditions in real time, allowing for predictive maintenance and avoiding costly downtime.

This kind of system intelligence is key to maintaining peak performance and aligning with Industry 4.0 standards.

For project managers tasked with retrofitting or specifying motors for new installations, here are essential factors to weigh:

Choosing the right motor for your application means balancing upfront costs with long-term savings and operational reliability.

VJ Pamensky connects Canadian industries with energy-efficient motor solutions that support modern operational needs. With access to WEG’s high-efficiency motor technologies, including Super Premium (IE4) and Ultra Premium (IE5) motors, and VFD-compatible systems, VJ Pamensky offers tailored solutions for industries seeking to reduce energy waste and improve system performance.

Whether you're managing a plant upgrade or planning a greenfield project, the right motor technology is a game-changer. Explore VJ Pamensky’s electric motor lineup to find energy solutions that power sustainable growth.

Efficiency is no longer optional, it’s essential. With evolving standards, smarter systems and high-performance materials, the electric motors of today are redefining what's possible in industrial automation. By working with trusted suppliers like VJ Pamensky, Canadian businesses can stay ahead of the curve and power their operations with confidence.

Contact VJ Pamensky today to explore advanced electric motor solutions that reduce energy costs, boost system performance and support your sustainability goals.