Selecting the correct motor is critical to the performance, efficiency and longevity of your industrial systems. For businesses across Canada and beyond, VJ Pamensky (WEG Canada) helps make the decision easier by guiding customers through the process of choosing the right WEG motor, backed by deep technical expertise and a thorough understanding of real-world application challenges.

From mining and oil & gas to food processing and manufacturing, WEG motors are designed with versatility and durability in mind. But choosing the right motor for your application takes more than just browsing a catalogue, it requires evaluating several performance and environmental factors.

The first step in selecting a WEG motor is defining the specific needs of your system. Start with three core performance factors:

Understanding these parameters ensures you're not over- or under-sizing your motor—both of which can shorten equipment life and increase energy costs.

WEG motors are engineered for efficiency, reliability and flexibility. Their designs prioritize:

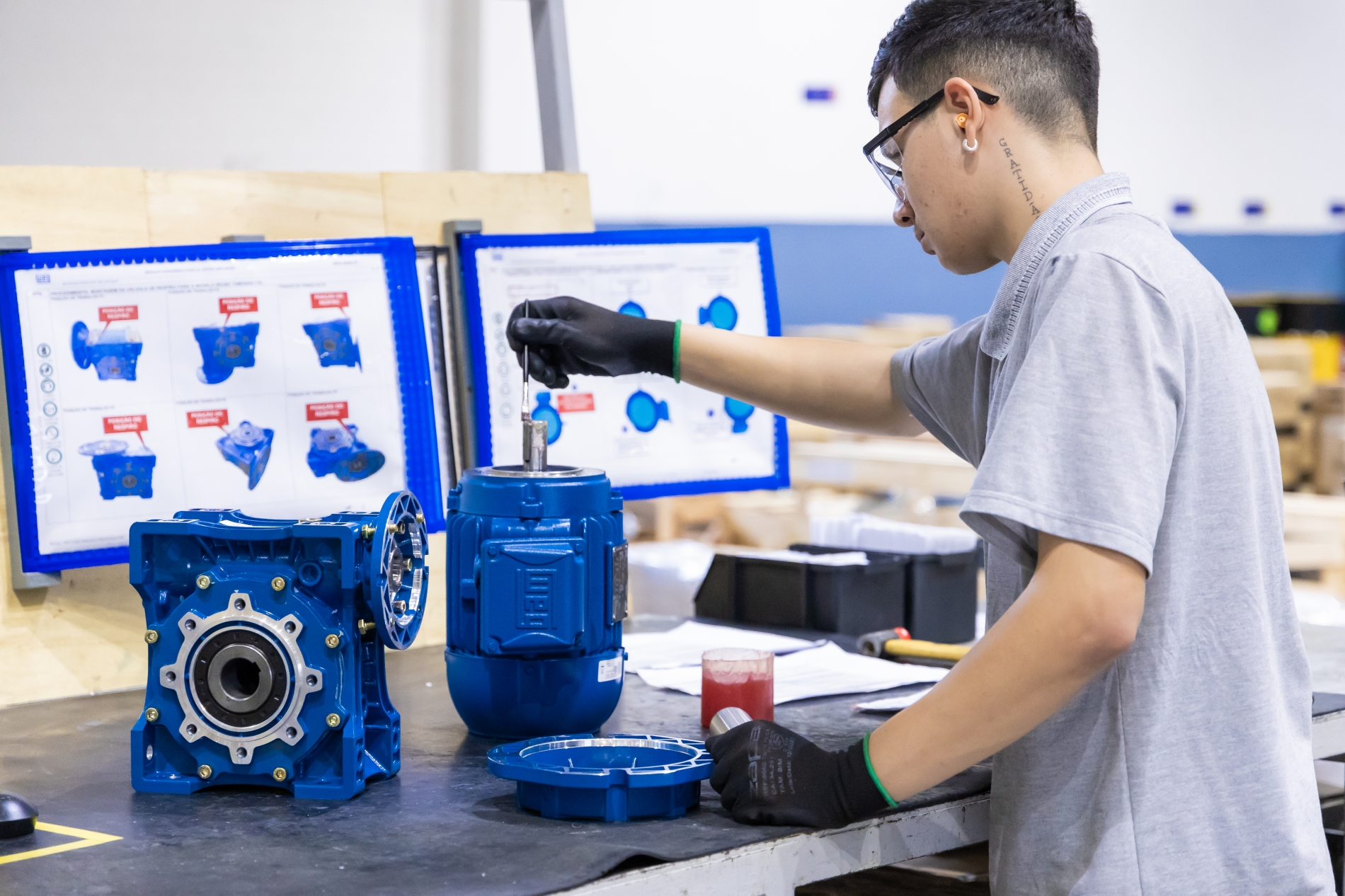

As an authorized distributor, VJ Pamensky helps clients select from WEG’s wide range of electric motors — including general-purpose, severe-duty and explosion-proof models — to find the best fit for each use case.

Not all motors are created equal, especially when it comes to harsh or hazardous environments. Factors like ambient temperature, humidity, dust, vibration and corrosive exposure all affect motor selection.

WEG motors offer solutions for:

By assessing environmental stressors early, you can avoid unexpected failures and downtime.

Modern industrial systems often incorporate variable frequency drives (VFDs) or soft starters to optimize motor control. It’s critical to ensure the selected motor is compatible with your automation setup.

VJ Pamensky’s team helps you:

This compatibility not only improves operational performance, it also extends motor life.

Initial motor cost is just the tip of the iceberg. Consider:

From troubleshooting to performance optimization, working with a trusted automation distributor like VJ Pamensky ensures you get support long after the motor is installed.

We are the exclusive Canadian importer of WEG products, bringing decades of experience in motor selection, supply, and integration. Our team understands the technical nuances of various industries and ensures that customers benefit from motors that:

From consultation to commissioning, we streamline the motor selection process, saving you time, money and headaches.

Choosing the right electric motor isn’t just about power ratings, it’s also about aligning performance with process demands, system integration and long-term reliability. WEG motors deliver the versatility and durability modern industries require and VJ Pamensky ensures every selection is backed by application-specific expertise.

Ready to find the right WEG motor for your needs? Contact VJ Pamensky today to speak with one of our product specialists.