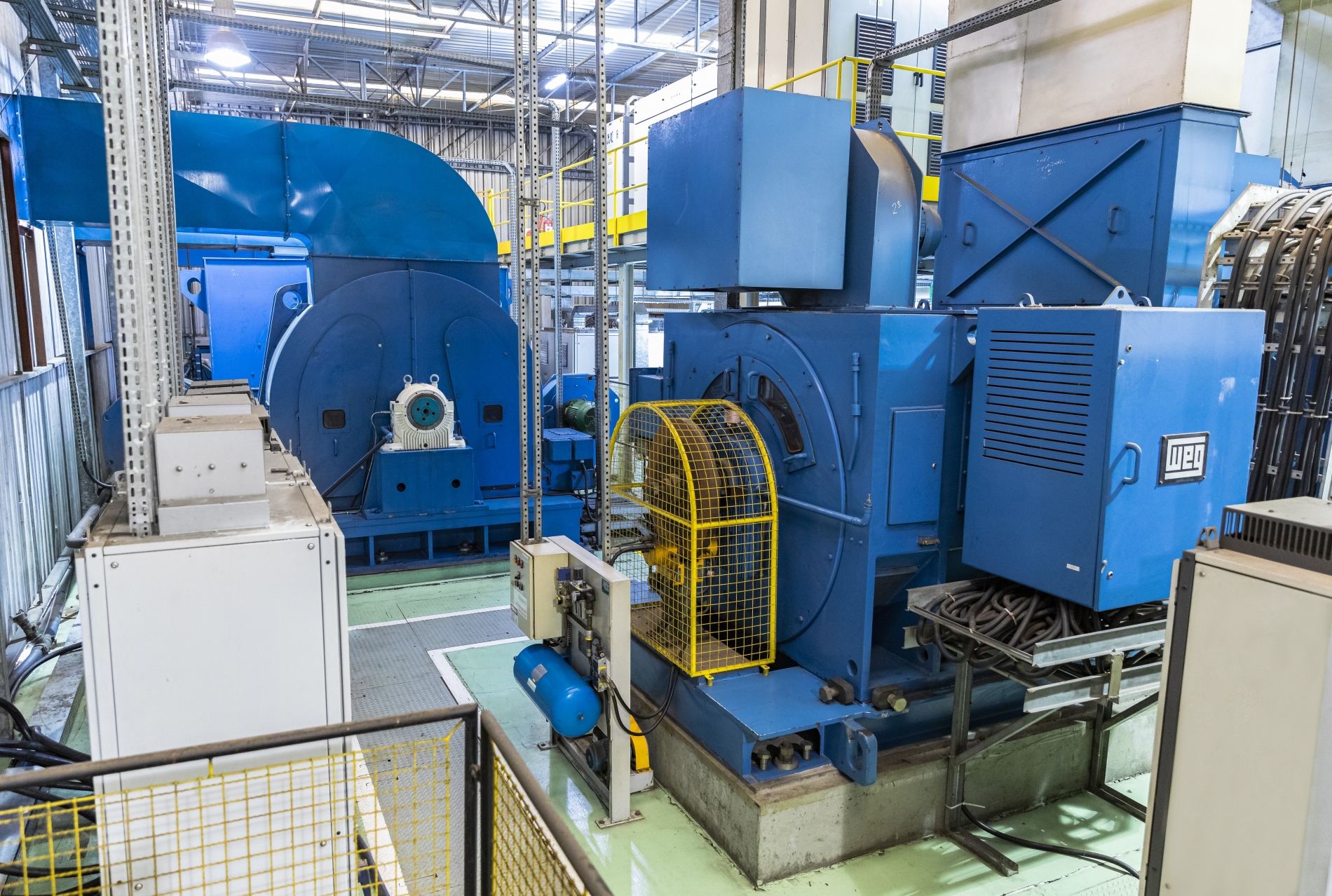

Electric motors have long been the backbone of industrial automation, powering everything from manufacturing lines to critical infrastructure. As industries increasingly demand greater efficiency and sustainability, material innovations are emerging as transformative forces. Companies like VJ Pamensky (WEG Canada), in collaboration with WEG, are leading this evolution, utilizing high-performance steel to redefine performance, reliability, and sustainability standards in electric motor design.

The quality of steel stator lamination plays a critical role in electric motor performance, directly impacting efficiency, durability, and energy savings. High-quality lamination enhances thermal capacity, reduces energy losses, and contributes to overall motor efficiency. To optimize performance and reduce long-term operating costs, WEG motors incorporate advanced lamination techniques, including C4 and C5 coatings.

WEG C4 and C5 laminations are designed to increase electric motor efficiency and durability. C4 is commonly used in high-power motors and welding machine transformers, while C5, which offers extra protection against corrosion, is ideal for power and distribution transformers. These coatings help WEG motors last longer, run more efficiently, and perform reliably in tough industrial conditions.

High-performance steel is another pivotal development. This material, known for its ability to minimize energy losses and resist heat, enhances the durability and reliability of electric motors. By integrating high-performance steel, WEG motors achieve a longer operational lifespan while requiring less maintenance, making them a cost-effective and eco-conscious choice for businesses.

WEG motors are designed with a focus on energy efficiency, aligning perfectly with the growing sustainability goals of industries worldwide. Furthermore, the sustainability edge of these motors makes them indispensable for businesses committed to eco-friendly manufacturing practices, reinforcing the role of WEG motors as leaders in this transformation.

Please check out our website for all industries we support.

As a trusted provider of industrial solutions, VJ Pamensky has built its reputation by delivering reliable, tailored products to meet the unique needs of industries across North America. Partnering with WEG, VJ Pamensky ensures its clients benefit from cutting-edge motors that leverage the latest material innovations. Together, they offer a competitive edge to sectors such as mining, oil and gas, and food and beverage by providing motors that excel in energy efficiency, reliability, and sustainability.

This partnership ensures that industrial businesses can seamlessly integrate advanced motors into their operations, supported by expert guidance from VJ Pamensky. Whether upgrading existing systems or designing new ones, the collaboration between VJ Pamensky and WEG represents a commitment to delivering solutions that address both present and future challenges in industrial automation.

The advancements in motor materials underscore the critical role of innovation in achieving sustainability. By incorporating high-performance steel that enhances energy efficiency and reduces waste, WEG motors, in partnership with VJ Pamensky, help industries meet environmental goals without compromising on operational performance. By utilizing advanced steel stator laminations and coatings like C4 and C5, WEG motors enhance energy efficiency and reduce maintenance costs. This results in a lower total cost of ownership, ensuring long-term reliability and sustainability for industrial businesses.

Material innovations, such as high-performance steel, are not just enhancing the quality of electric motors; they are driving a new era of industrial automation. With WEG motors at the forefront, supported by the expertise of VJ Pamensky, businesses can achieve superior efficiency, reliability, and sustainability. As industries continue to evolve, these innovations stand as a testament to the possibilities of engineering excellence and environmental responsibility working hand in hand.

Ready to optimize your industrial systems with WEG motors? Contact Pamensky (WEG Canada) today for tailored solutions that prioritize performance and sustainability.