In today’s fast-paced industrial landscape, reliability and performance are essential for businesses aiming to maintain efficient operations. At the heart of this need is one of the most fundamental components of industrial automation: electric motors. Pamensky delivers consistent, high-quality motors that industries can depend on, addressing the demands of a market that requires both exceptional performance and trusted support.

Pamensky recognizes that the performance and reliability of an electric motor are shaped by the technology driving it. That’s why they have partnered with WEG who is recognized for its commitment to innovation, investing in advanced materials, manufacturing techniques, and comprehensive research and development to meet and exceed industry standards. As industrial sectors continue to evolve, Pamensky ensures that the latest motor technology reaches clients in diverse fields such as mining, oil & gas, food & beverage, and industrial automation.

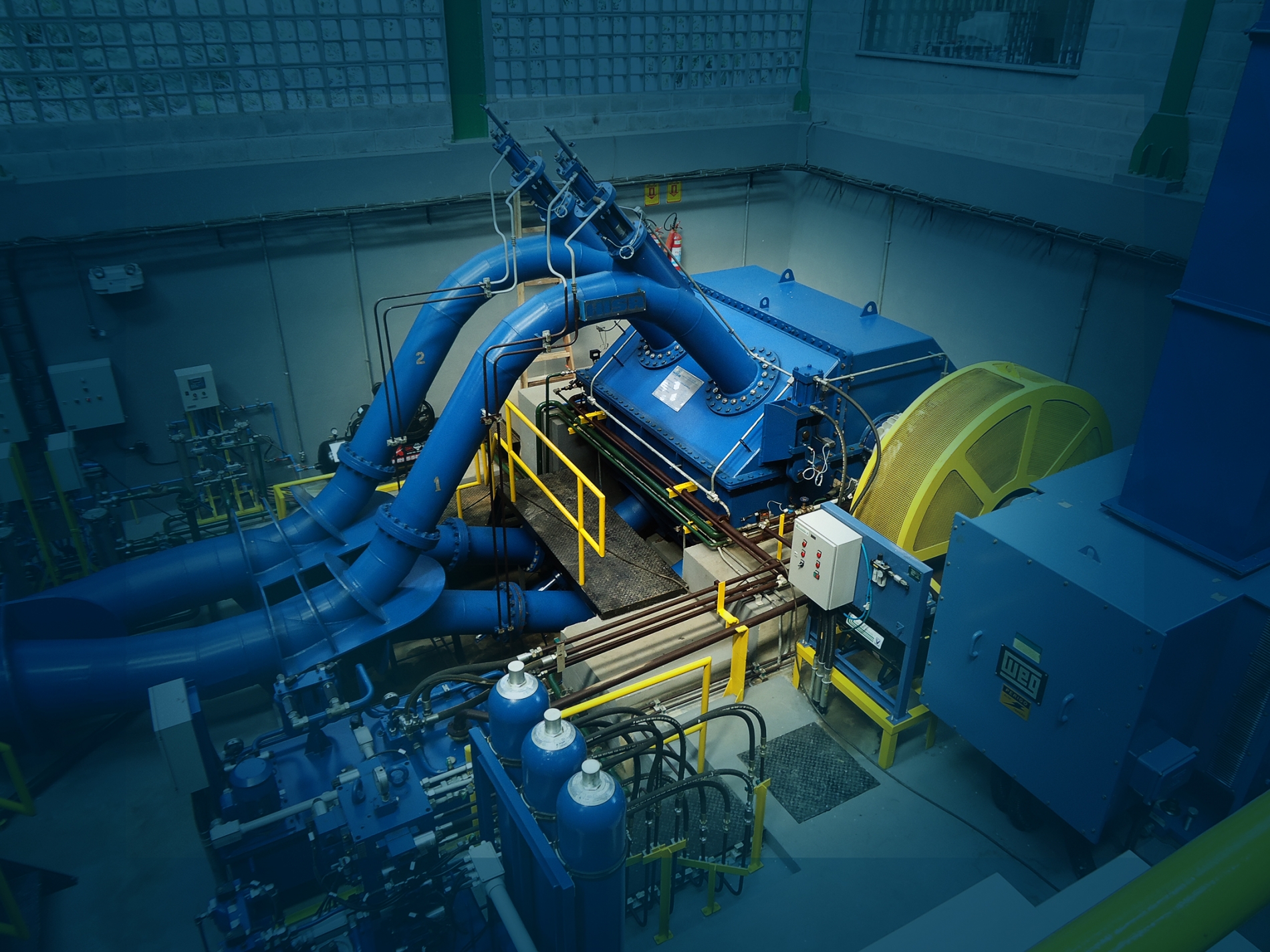

Pamensky motors are engineered to excel under harsh conditions, thanks to WEG’s design philosophy that prioritizes energy efficiency, long operational lifespans, and reduced maintenance requirements. Pamensky’s dedication to providing the best in-class technological advancement ensures that each motor they supply not only meets the demands of industrial applications but does so consistently, offering a blend of performance and durability that is crucial for continuous operation. By integrating state-of-the-art technology and addressing the specific needs of various industrial environments, Pamensky motors deliver a level of quality that aligns with the high expectations of the industry.

Pamensky's approach to quality involves more than just superior engineering; it encompasses an unwavering commitment to testing and validation. Pamensky partnered with WEG because of their extensive testing protocols before reaching the market, ensuring they can withstand the most challenging conditions. These tests are designed to replicate real-world industrial environments, where motors must endure extreme temperatures, moisture, and sustained operational demands.

By partnering with manufacturers that focus on rigorous testing, Pamensky guarantees that each motor performs reliably from installation onward, reducing the likelihood of unforeseen downtime and maintenance costs. This focus on uncompromising quality helps industrial clients avoid the disruptions that can occur from unexpected equipment failures, allowing for smoother and more predictable operations. Pamensky's commitment to quality testing ensures that every motor delivered not only meets technical requirements but also upholds a standard of excellence that reflects the company’s dedication to long-term customer satisfaction.

Pamensky has established itself as a leader in delivering electric motors that power industries across North America. However, the company’s approach goes beyond simply supplying products; it involves offering solutions tailored to the unique needs of each client, enabling businesses to optimize their operations with motors that are fit for purpose. By understanding the distinct challenges faced by industries—whether it’s the need for heavy-duty motors in mining, precise automation requirements in manufacturing, or the rugged demands of oil & gas—Pamensky provides motors that are carefully matched to each application.

This commitment to tailoring solutions is backed by an understanding of the factors that influence motor selection. From the technical requirements of engineers to the operational needs of end-users, Pamensky ensures that its motors deliver the right balance of power, efficiency, and durability. The company’s close collaboration with customers allows it to address specific operational goals, ensuring that each motor not only meets expectations but also enhances overall productivity and system efficiency.

In any industrial setting, even the smallest component failure can have significant implications for operations, leading to costly downtime and delays. Pamensky addresses this challenge by prioritizing consistency in every motor delivered. This consistency is not just about maintaining high quality; it’s about ensuring that each motor performs as expected throughout its lifecycle. With Pamensky motors, clients can be confident that they are investing in products designed to deliver steady, dependable performance in demanding environments.

Pamensky’s commitment to reliability extends to its customer service and support, providing assistance at every stage of the motor lifecycle—from selection and installation to maintenance and beyond. This holistic approach to quality and service helps clients avoid the operational pitfalls associated with motor failures, providing peace of mind and minimizing the total cost of ownership. By consistently delivering motors that perform to the highest standards, Pamensky reinforces its reputation as a trusted partner in industrial automation.

As industries increasingly prioritize sustainability, Pamensky is leading the way by providing motors that support energy-efficient operations. Motors supplied by Pamensky are designed to help businesses reduce their energy consumption without sacrificing performance, contributing to a lower carbon footprint while also cutting operational costs. This focus on sustainability is not just about meeting regulatory requirements; it is about enabling industries to operate more responsibly and efficiently.

The energy efficiency of Pamensky motors aligns with a growing need for sustainable solutions in industrial applications, helping companies not only achieve compliance but also improve their overall environmental impact. By choosing Pamensky motors, businesses can be assured that they are investing in technology that supports their sustainability goals, while still providing the robust performance needed for critical operations. The integration of energy-efficient motors into industrial systems allows for a proactive approach to sustainability, ensuring that businesses are equipped for the future.

When it comes to powering industrial applications, reliability is non-negotiable. Pamensky’s dedication to delivering top-tier electric motors ensures that industries across North America can count on consistent performance and long-term durability. Through a combination of advanced technology, rigorous testing, and tailored solutions, Pamensky stands out as a trusted partner for businesses seeking dependable motors to drive their operations. With a commitment to quality and sustainability, Pamensky continues to support the evolving needs of its clients, helping them achieve operational excellence and sustainable growth.

If you're looking for reliable, high-performance motors for your industrial applications, contact Pamensky (WEG Canada) today to discover how our motors can support your business.