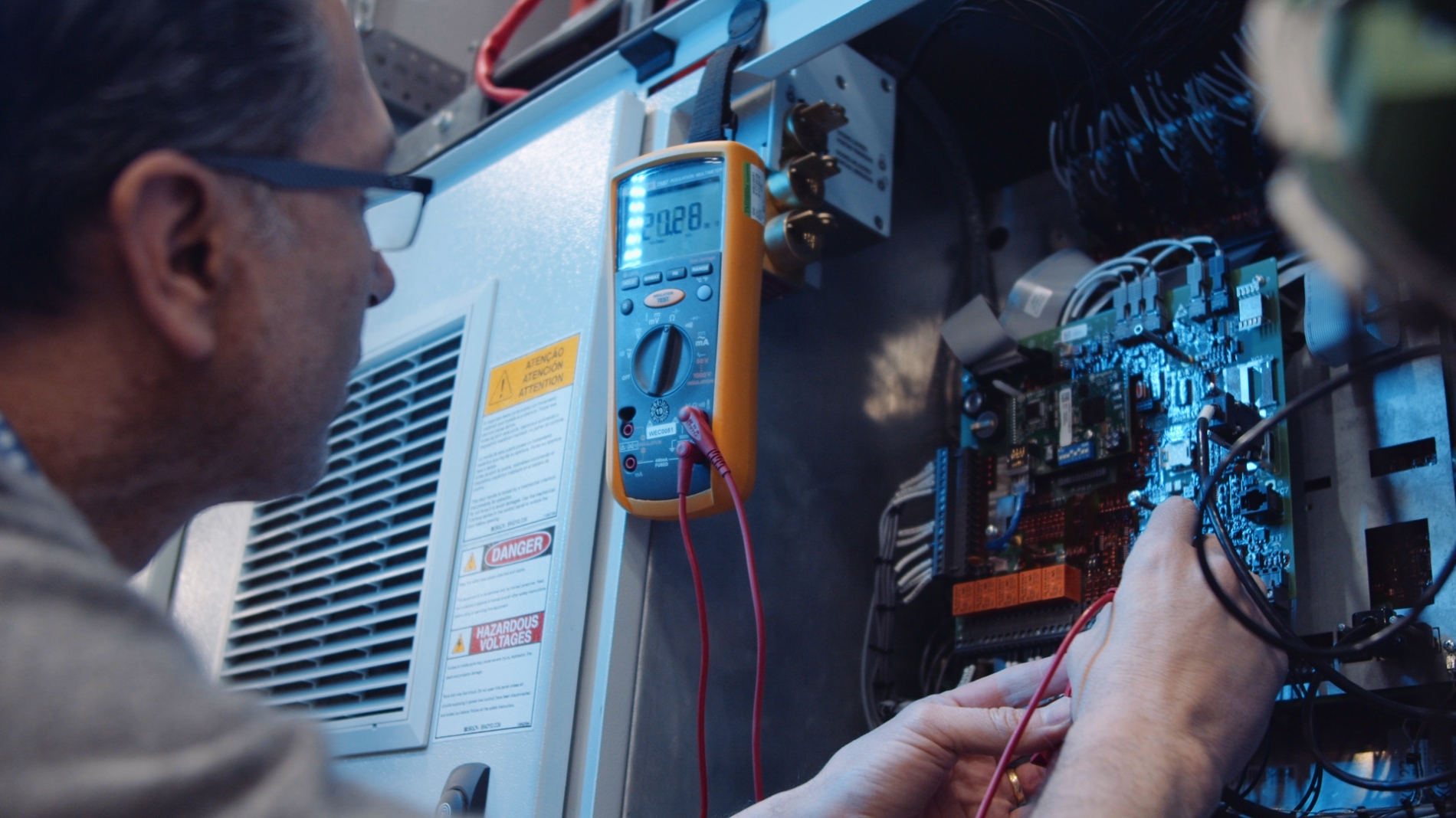

Variable Frequency Drives (VFDs) have become essential in optimizing motor control, reducing energy consumption and extending equipment life in industrial automation systems. VJ Pamensky (WEG Canada) supports businesses across industries like mining, oil & gas and manufacturing by helping them select, install and maintain VFDs for optimal performance. In this blog, we explore the most common VFD issues and how to resolve them to ensure reliability and efficiency.

VFDs can introduce harmonic distortion into a facility’s electrical system, especially in high-load environments. This distortion leads to equipment overheating, nuisance tripping and reduced power factor.

Solutions:

Extended cable lengths between VFDs and motors can lead to voltage spikes due to reflected wave phenomena. These spikes often stress or damage motor insulation, especially in older motors.

Solutions:

VJ Pamensky can recommend compatible filters and motor types for your cable setup.

Overheating is common when VFDs are installed in tight or poorly ventilated enclosures. This issue worsens in hot industrial environments and can lead to premature failure.

Solutions:

VJ Pamensky helps customers assess installation conditions to prevent thermal issues.

High-frequency switching in VFDs can cause electromagnetic interference (EMI), which may disrupt nearby sensitive equipment.

Solutions:

Incorrect VFD parameter settings — such as acceleration time, torque limits or braking functions — can lead to operational inefficiencies or mechanical damage.

Solutions:

Reach to our team of Automation Specialists to acquire the best possible support.

From selecting the right drive to optimizing parameter settings, VJ Pamensky offers expert support to maximize VFD performance while minimizing risks. Our team helps:

Explore our VFD and motor control solutions to learn how we can support your next automation project.

VFDs offer immense value in energy savings and automation control — but only when applied correctly. VJ Pamensky provides the guidance needed to prevent common VFD failures and extend equipment life.

Ready to ensure your next VFD installation runs smoothly? Contact VJ Pamensky today to speak with a specialist.