In the fast-paced world of energy solutions and industrial automation, maintaining the operational integrity of electric motors is paramount. Enter smart diagnostics and proactive maintenance—the future-now solutions revolutionizing motor service. By harnessing cutting-edge technology, companies like Pamensky (WEG Canada) provide innovative tools to predict and prevent potential issues.

Motor diagnostics have undergone a remarkable transformation, pivoting from reactive measures—often taken after failure—to a proactive stance. They provide advanced algorithms for failure diagnosis and energy analysis, which enable continuous monitoring and real-time analytics on potential issues such as misalignment, imbalance, bearing failure, external vibration, and poor lubrication. By prioritizing preventative motor diagnostics, you can sidestep costly repairs, saving time and money in the long run.

In the progressive realm of industrial automation, adopting predictive analytics marks a transformative era, reshaping how businesses operate. This cutting-edge approach utilizes historical data, statistical algorithms, and machine learning to forecast future events, optimize resource usage, and enhance decision-making with its prescient insights. Real-time, accurate predictions facilitate proactive risk management and enable industrial managers to rapidly refine product lines and processes.

In the age of the Internet of Things (IoT), interconnected devices provide a constant stream of operational data. This means an ongoing dialogue between motors and maintenance crews—ensuring each part functions at its peak, catching irregularities, and scheduling maintenance activities before problems escalate.

The advantages of smart diagnostics are multifold, including but not limited to:

Electric motors are the industry's powerhouse, and their longevity is crucial. Smart diagnostics play a vital role in extending a motor's service life. By consistently monitoring motor health and addressing the minutest anomalies immediately, the technology adds years to motor operation, maximizing businesses' return on investment.

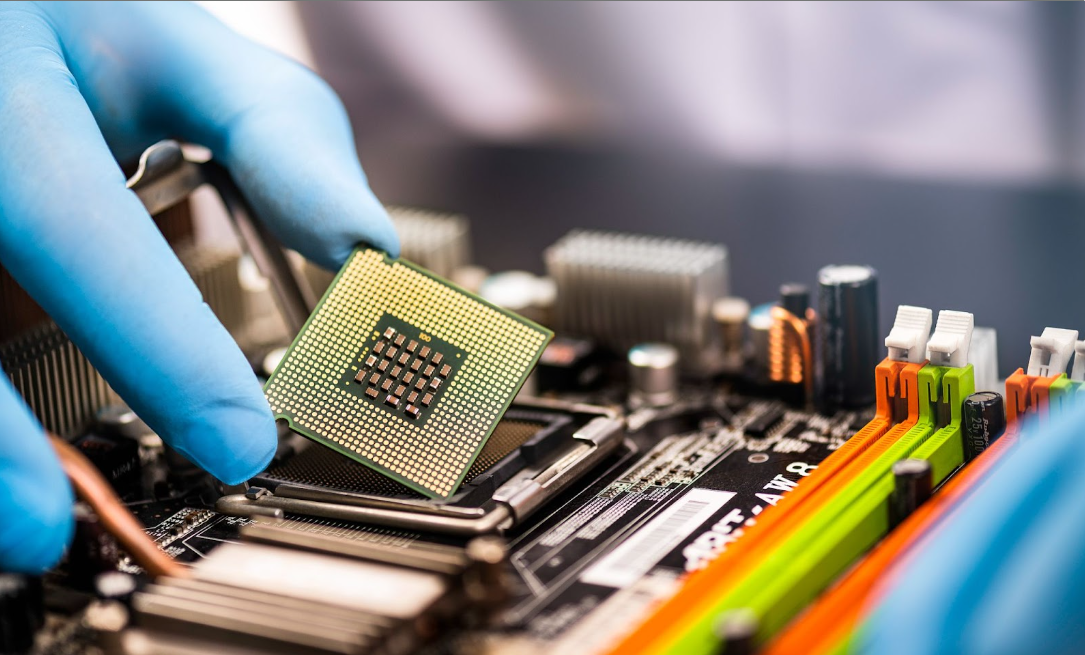

At the core of smart diagnostics lies a suite of technologies—sensors that detect vibration, temperature, and electrical currents, along with AI-driven analytics that process this data, predicting when parts might fail or require service. This predictive capability provides companies with foresight that was once unimaginable.

A strategic alliance with industry leaders like Pamensky (WEG Canada) is invaluable for adopting this innovative approach. The partnership ensures access to expertise, support, and industry-leading motor solutions embodying technological prowess and reliability.

The synergy of smart diagnostics and proactive maintenance is essential to modern motor service. It's a proactive path that leads to increased uptime, cost savings, and heightened motor performance. As companies in the energy solutions and industrial automation sectors forge ahead, aligning with knowledgeable and innovative partners such as Pamensky (WEG Canada) will be vital to navigating the complexities of motor maintenance. Embrace the power of technology and let it transform your operations, ensuring that every motor serves you longer, better, and smarter.