For OEMs operating in Alberta’s harshest conditions, being able to navigate motor selection for industrial automation and energy-intensive systems is key. Edmonton’s energy and resource sectors are at the heart of Canada’s industrial economy. Known for its oil sands, natural gas processing and heavy manufacturing, Edmonton is a pivotal hub for Original Equipment Manufacturers (OEMs) designing equipment for high-demand, rugged environments. To meet these challenges, selecting the right motor is not just a performance decision, it’s a long-term strategic investment. VJ Pamensky (WEG Canada) provides critical support, ensuring Edmonton electric motors deliver the reliability and performance these applications demand.

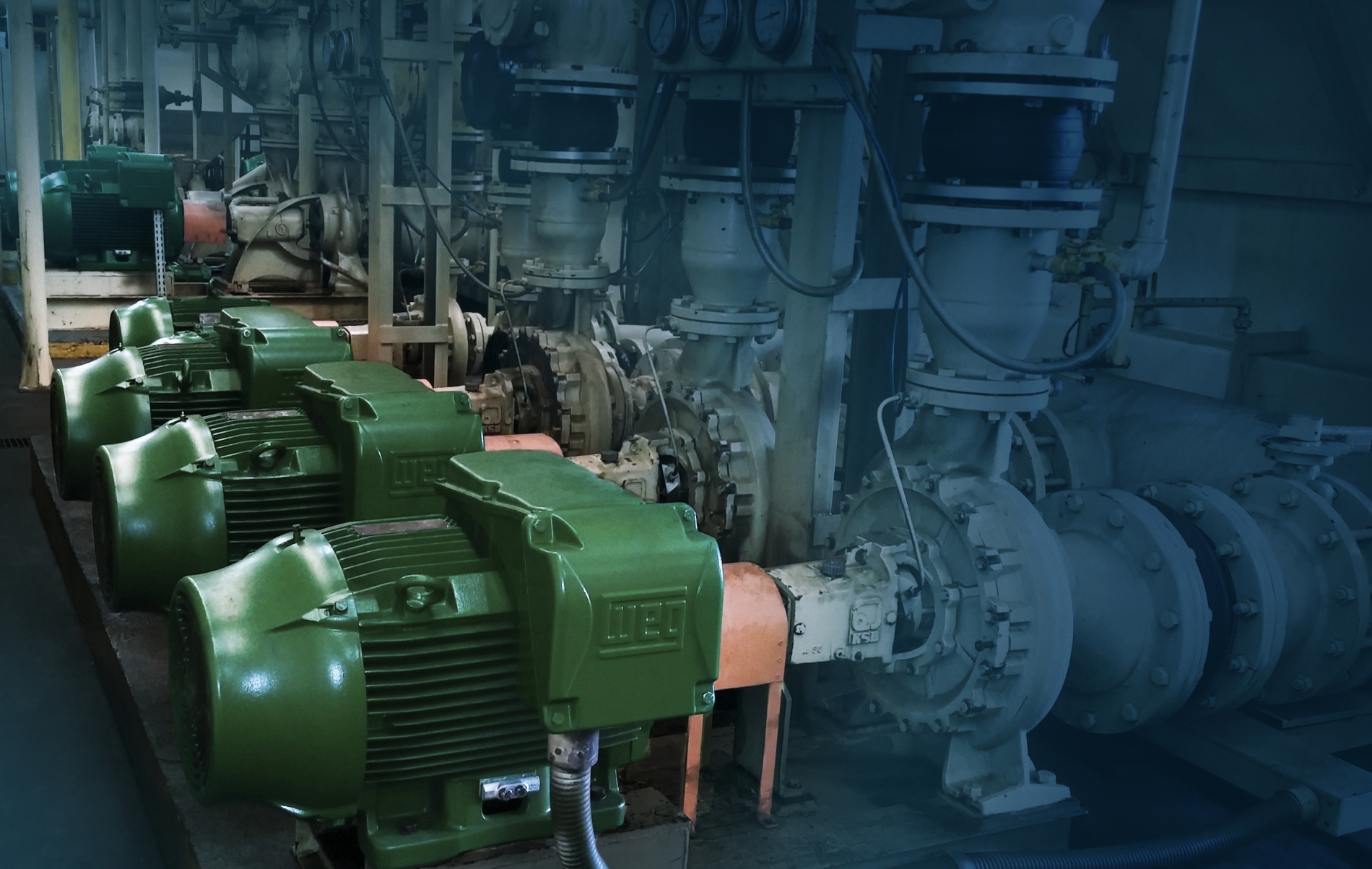

As Alberta’s capital, Edmonton is a powerhouse for oil, gas and pipeline infrastructure, with strong ties to petrochemical refining and energy generation. These industries operate in environments where temperature fluctuations, vibration, contamination and extended run-times are the norm. OEMs here face unique performance challenges when integrating motors into compressors, conveyors, pumps and drilling systems. Equipment failure is costly and can lead to safety risks and significant downtime.

To thrive in Edmonton’s energy sector, motors must exceed standard specifications. Key performance features to prioritize include:

Choosing motors built with these specifications ensures performance longevity and mitigates unplanned maintenance.

Extreme environments demand motors built to global quality standards. While VJ Pamensky is an independent distributor, it leverages the proven engineering of WEG motors, known for their robust construction and performance efficiency. High manufacturing standards translate to:

These qualities matter when motors are deployed in remote or hazardous environments typical of Edmonton’s industrial zones.

Beyond technical specs, local availability and service make all the difference. VJ Pamensky ensures Edmonton OEMs get access to:

This localized support minimizes downtime and accelerates implementation for fast-moving projects.

As Alberta's industries pursue carbon reduction and cost optimization, OEMs are shifting toward motors with high energy efficiency and low maintenance demands. Investing in energy-efficient motors now supports long-term sustainability goals while reducing operational expenses. Motors that meet or exceed NEMA efficiency ratings provide measurable performance returns over time.

To future-proof operations, OEMs in Edmonton should align motor selection with both present-day demands and evolving regulatory standards.

In Edmonton’s energy-intensive economy, motor selection is a mission-critical decision. OEMs must account for harsh environments, performance specifications and future efficiency needs. With expert support from VJ Pamensky, Edmonton manufacturers can access rugged, high-quality electric motors built to thrive under pressure.

Contact VJ Pamensky today to find industrial motors built for Edmonton’s toughest environments.