Electric motors are the heartbeat of modern industrial automation—but even the most robust units aren’t immune to failure. For distributors and resellers supporting sectors like mining, oil & gas, and food processing, understanding motor failures is critical to delivering timely, effective solutions. VJ Pamensky (WEG Canada) has a strong track record of supplying high-performance electric motors, and with the right insight, you can help customers minimize downtime and extend equipment lifespan.

Overheating

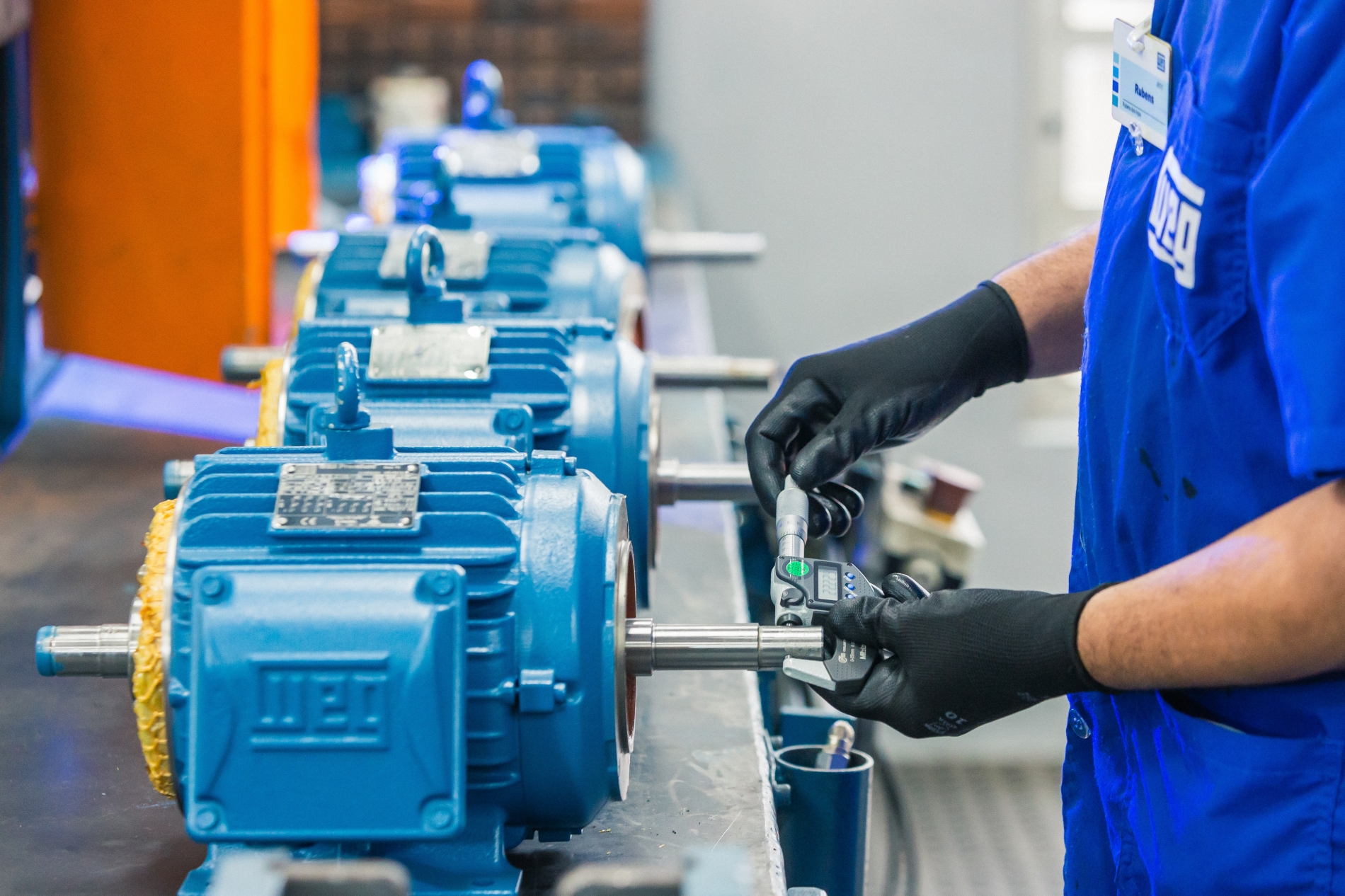

Bearing Failure

Insulation Breakdown

These failures account for over 43% of electric motor issues across industrial applications.

Preventable issues like dirt ingress, lack of lubrication and infrequent inspection accelerate motor wear. For customers relying on continuous operations, a single motor failure can cost hours of productivity. Resellers and automation distributors play a crucial role by recommending proactive solutions such as scheduled maintenance plans, proper storage and environmental protection kits.

Providing value-added guidance like this can strengthen customer trust and reduce return claims.

Distributors serve as frontline problem-solvers, helping clients source the right electric motors and offering technical support on issues like performance optimization and energy efficiency. By aligning with trusted manufacturers like WEG, you gain access to advanced tools and technical data that enhance your advisory capabilities.

While WEG offers global expertise in motor technology, VJ Pamensky operates independently in Canada with tailored support, deep inventory and decades of experience in the field. Distributors who partner with VJ Pamensky can offer clients timely access to WEG motors, expert insights and localized service advantages.

Explore more about electric motor options and specifications.

By incorporating these practices, distributors not only extend the life of electric motors, they also position themselves as indispensable partners in industrial automation.

Electric motor failures don’t have to derail operations. As an automation distributor, your proactive guidance—paired with reliable products from trusted suppliers—can dramatically reduce downtime for your customers. From identifying early warning signs to recommending the right WEG motors, your expertise positions you as a key ally in industrial success.

For expert advice or to explore tailored electric motor solutions, contact VJ Pamensky today.