In the rapidly evolving landscape of industrial automation, Original Equipment Manufacturers (OEMs) are under increasing pressure to deliver systems that are smarter, faster and more energy-efficient. At the heart of this innovation lies a proven workhorse: the AC motor. VJ Pamensky (WEG Canada) continues to support OEMs by providing reliable, high-efficiency AC motors that are built for modern control environments and demanding industrial applications.

AC induction motors are the industry benchmark for automated systems across sectors like manufacturing, robotics and material handling. Their robust construction, high reliability and ability to run directly from the grid make them ideal for continuous operations. Unlike DC motors, AC motors require less maintenance, have a simpler design and are more cost-effective over their lifecycle, critical factors for OEMs focused on system uptime and cost control.

The integration of Variable Frequency Drives (VFDs) has elevated the role of AC motors in automation. VFDs allow precise control over motor speed, torque and direction, enabling real-time adjustments based on load conditions or system requirements. OEMs can now fine-tune performance to meet exact specifications, reducing energy consumption and mechanical stress.

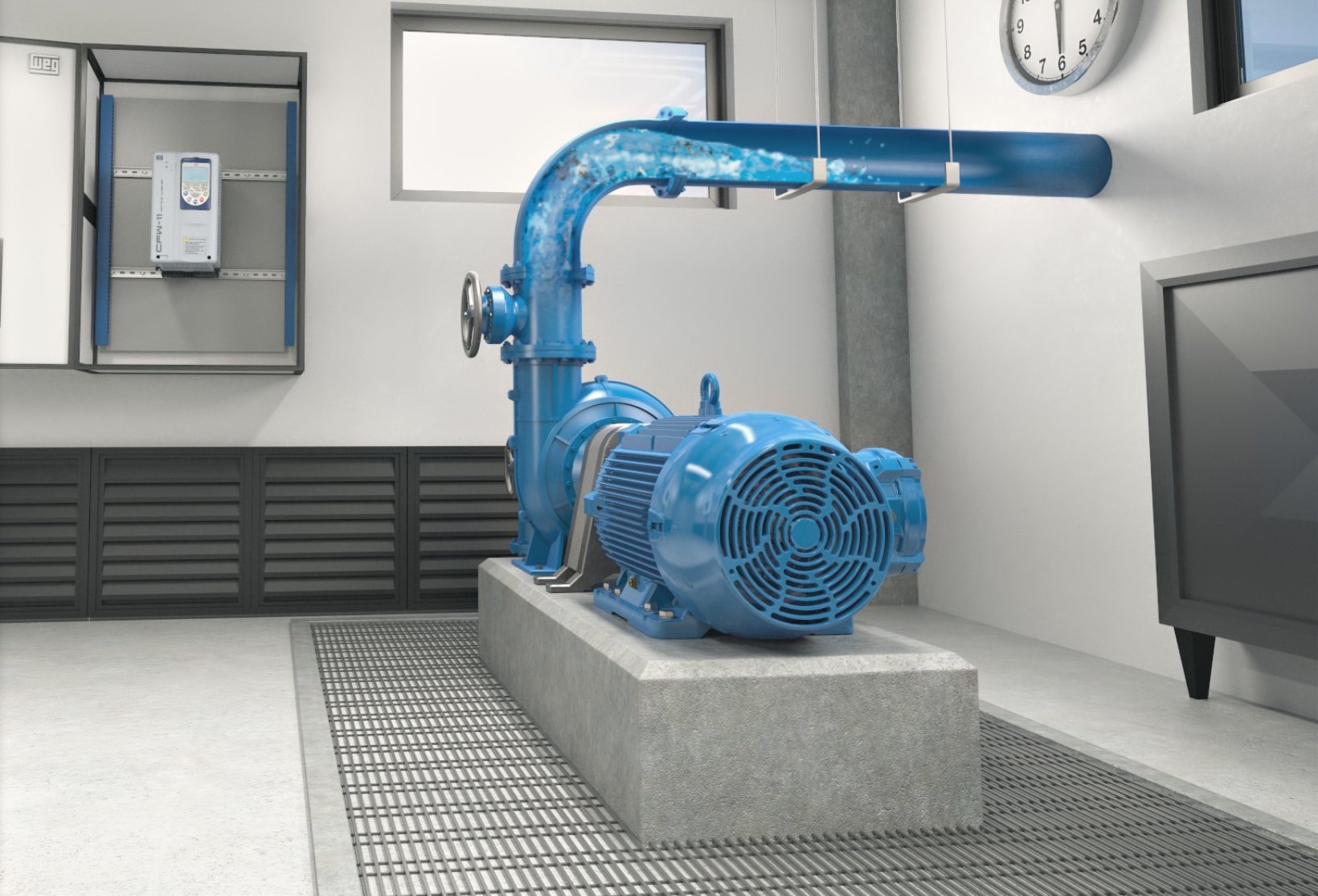

This seamless VFD compatibility is especially valuable in systems like automated conveyors, pump assemblies and robotic arms where precision and flexibility are non-negotiable. Paired with VFDs, AC motors offer smoother starts, consistent speed regulation and the ability to handle variable loads, all of which contribute to improved system longevity and reduced downtime.

Today’s generation of high-efficiency motors represents a significant leap forward for energy-conscious OEMs. These motors are engineered to meet NEMA Premium efficiency standards, making them suitable for regulatory compliance and sustainability goals. Reduced heat generation, improved insulation and optimized rotor design contribute to better performance and lower operating costs.

By upgrading to premium-efficiency AC motors, OEMs can minimize power losses and extend equipment life, aligning with sustainability objectives without compromising output or control capabilities.

AC motors are exceptionally versatile, making them suitable for a wide range of OEM applications, including:

Their modularity and ease of integration also make them well suited for OEMs designing scalable solutions for food and beverage, mining and industrial HVAC systems.

One of the most compelling advantages of AC motors in OEM automation systems is their low maintenance requirements. With fewer moving parts and no brushes, AC motors experience less wear and tear compared to their DC counterparts. This leads to fewer service interruptions, lower lifecycle costs and enhanced system uptime, a critical priority for OEMs operating in competitive markets.

Additionally, compatibility with smart monitoring solutions allows for predictive maintenance strategies, further reducing unplanned downtime and extending the service life of both the motor and the overall system.

Contact VJ Pamensky today to explore our range of AC motors for industrial automation and discover how we support OEMs in achieving next-level performance, control and energy efficiency.

AC motors are well-suited for OEM applications due to their robust performance, high reliability and ease of integration with automation systems. Their low maintenance design and compatibility with modern control technologies make them a cost-effective choice for industrial automation.

A Variable Frequency Drive (VFD) enhances AC motor performance by allowing real-time control of speed and torque. This not only improves precision and flexibility in operations but also contributes to energy efficiency and extended equipment life.

Yes. High-efficiency AC motors reduce energy consumption and operational costs, helping OEMs meet regulatory standards and sustainability goals. Their improved thermal management and durability also lead to longer service life and reduced downtime.

OEM equipment such as conveyor systems, robotic arms, pumps and compressors benefit significantly from AC motors. These motors provide consistent torque, responsive control and long-term reliability in a wide range of automated systems.

AC motors have fewer moving parts and no brushes, which reduces mechanical wear. This results in less frequent maintenance, longer operational periods between service intervals and lower overall maintenance costs for OEMs.